Rugged DS Series Couplings Are Ideal for Motion Control Applications

DS Series Couplings Are Designed for High-Performance Motion Control Applications.

The DS Series works exceedingly well in applications requiring a flexible coupling that combines superior torque capacity and high torsional stiffness, without the weight and inertia of a stainless steel coupling. Since acceleration rates are higher in today’s motion control systems, lower inertia of individual components means a more responsive system. The DS Series meets these requirements for outstanding performance with minimum coupling inertia. Motion control applications that require connecting motor and leadscrews and/or leadscrew and encoders are the focus of the DS series.

DS Series Couplings in Motion Control Applications

The product affords the designer substantial .010-inch parallel offset capability, reducing the need for high precision alignment during assembly operations. It also accommodates three degrees of angular shaft misalignment and permits axial motion of ±.008″. Outside diameters are provided in 3/4″, 1″, 1 1/4″, 1 1/2″ and 2″ sizes.

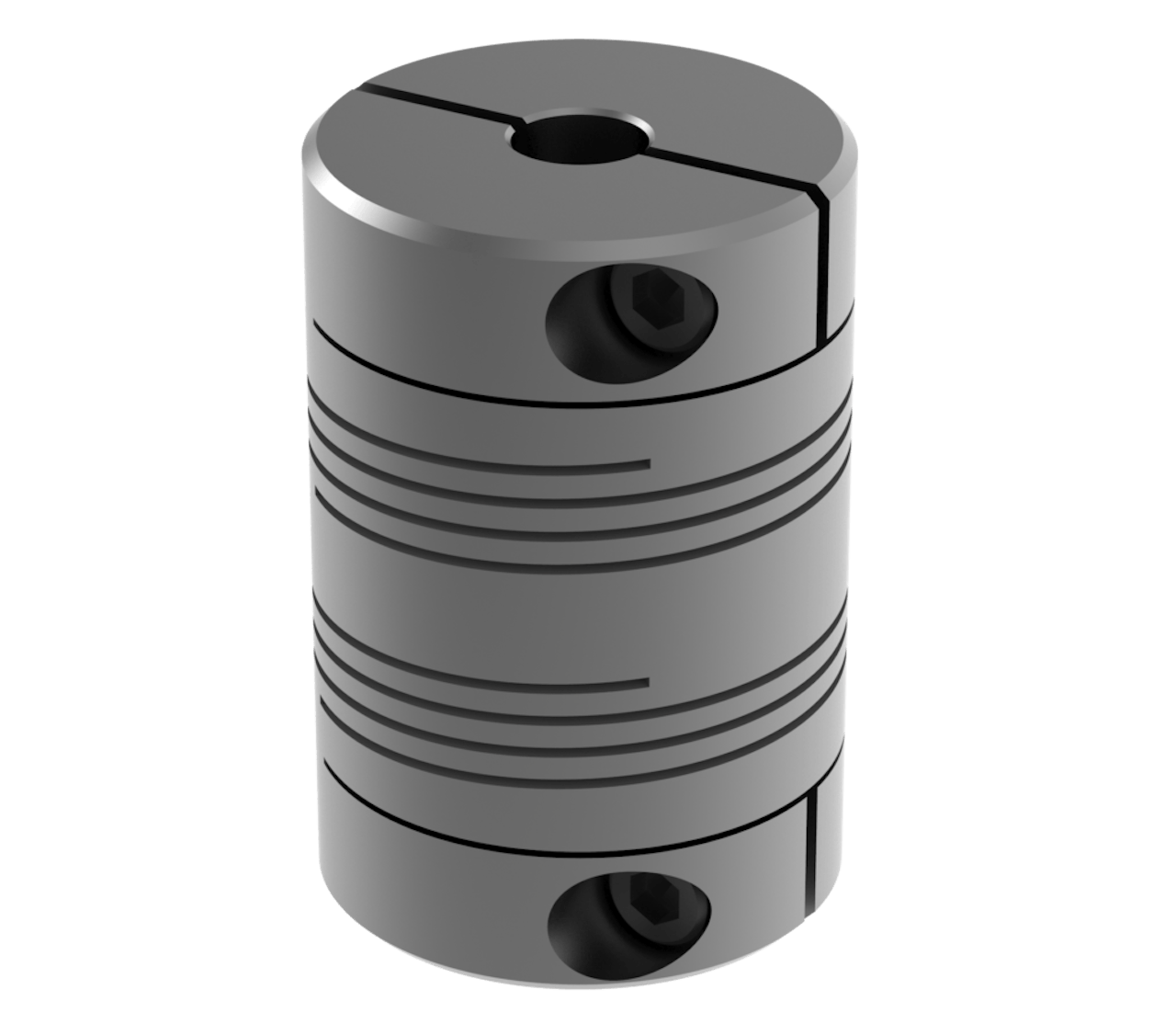

The DS Series is different from any other coupling in the Helical coupling lineup; it is the only series to use a multi-start flexure design. In this case, the DS Series has a “Double Start” flexure, which is where the designation “DS” is derived. In this configuration, each flexure consists of two coils that start 180 degrees from each other so as to maximize parallel misalignment capability without sacrificing performance. Combining these flexures in this manner enables the coupling to operate at a high-performance standard.

The DS Series is a full-featured coupling that includes the popular Integral Clamp attachment and a Relief bore configuration. The Integral Clamp is a great method to attach the coupling to a shaft. Tightening down the socket head capscrew of the clamp draws it down onto the shaft for a positive friction connection. By simply loosening the capscrew the coupling can be conveniently removed or repositioned, as needed, to satisfy any application. The relief configuration allows the shafts to enter into the flexure area making installation easier because the distance between shafts is not critical.

When looking for the best value in a coupling to meet the demands of the newest designs of motion control applications, the DS Series is well worth your consideration.

Shop OnDemand Couplings or Request a Quote to customize a coupling for a specific application.

Ask an Expert

Have questions about specialty materials, machining capabilities, bore configurations, or others? Contact an MW Expert to find out more.