Helical Products

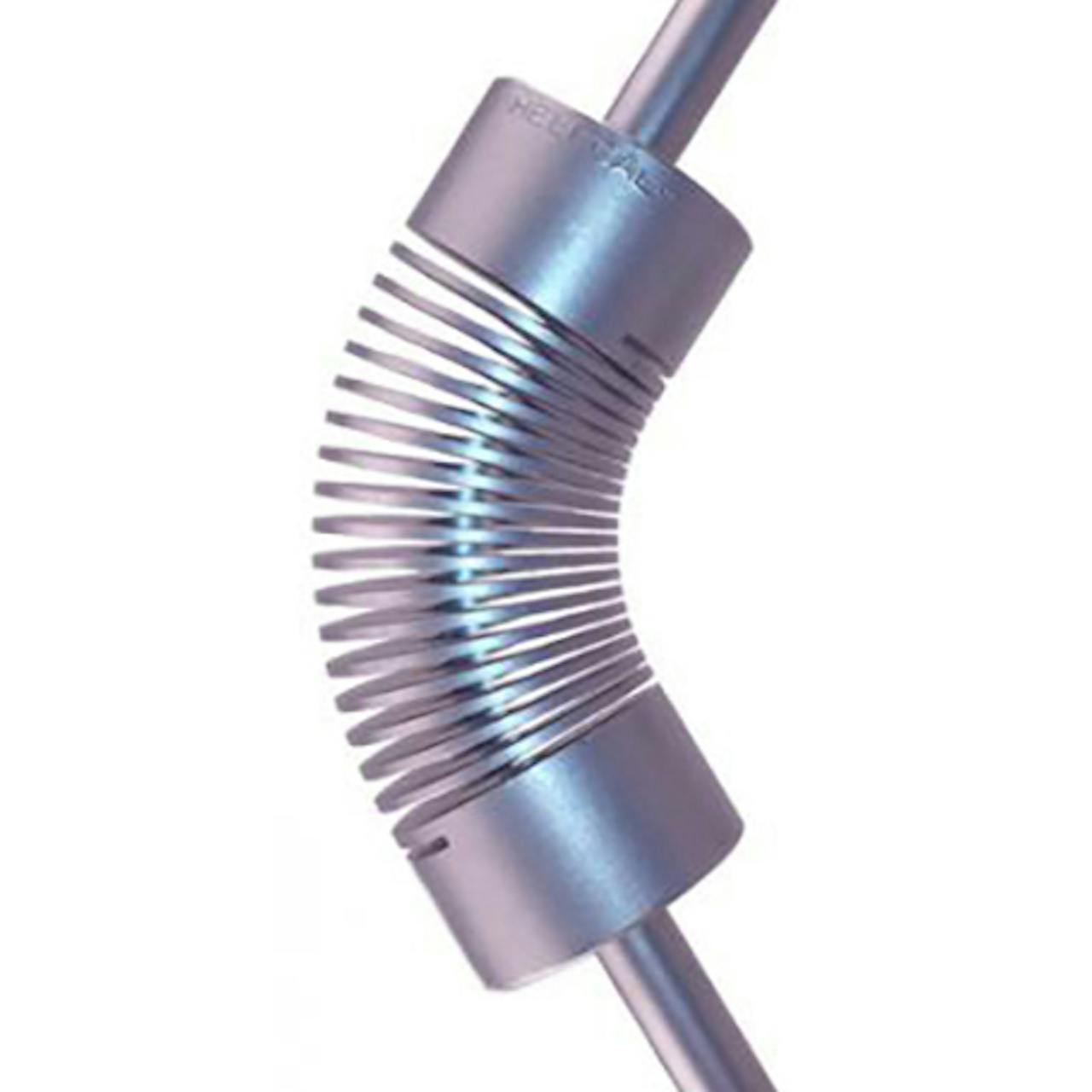

Helical Products has a rich history of innovation, starting in the 50s with the development of machined springs, which offer a single-piece solution that outperforms traditional wire-wound springs. Helical Products now uses the same technology to produce various flexible components, including flexible couplings and U-joints. We offer standard couplings and U-joints for convenient, fast delivery. And as a custom manufacturer, with a variety of industry experience and a team of in-house engineering experts, we're also ready to work with you on custom solutions designed specifically for your needs.

Custom Machined Springs and Couplings

The Helical machined spring offers endless customization possibilities due to its proprietary production process. Machined springs are produced by machining solid bar stock to your desired requirements, including the number of coils, coil spacing, and ID and OD measurements. Unique to machined springs, we can also include a number of end attachments all in a single-piece solution, allowing your machined spring to perform multiple functions without the need for added assemblies.

Our custom couplings are designed and engineered for your OEM application to your exact specifications. They're produced with our original flexure technology, engineered for elasticity, and produced to the highest quality standards. Our production facility is AS9100 and ISO 9001 certified and offers a variety of on-site testing to ensure the longest possible cycle life of each part produced.

Request a quote to get started.

Coupling Selector

Helical Products produces a variety of beam couplings or Helical couplings available for fast shipping direct to you, including various sizes, torque options, attachments, and materials. Configure a coupling using our coupling selector tool which allows you to configure settings for OD, length, bore diameter, torque, select attachments, and more. Start by selecting "configure a coupling" below.

Need help determining the right specifications for your coupling or looking for an entirely custom solution? Request a custom quote.

Request a Prototype

Looking to develop a test part or prototype? Request a prototype based on the primary function of your part.

Why Helical Products?

In 1958 Helical invented the beam-style flexible shaft coupling by using a novel concept, machining bar stock, to produce a spring-like flexure thus developing the original method to produce our versatile HELI-CAL® flexure. Tens of thousands of configurations were designed and further evolution of the flexure continued. Learning that additional coils could be added to the HELI-CAL flexure for greater misalignment led to the U-joint product line, capable of torque transmission up to a 90-degree angle. Further development of the manufacturing process led to a HELI-CAL® flexure with precise spring rates in compression/extension, torsion, bending, etc. From this, the unique and revolutionary HELI-CAL Machined Spring® has evolved, which now includes options for multiple coil starts.

Our rich history of innovation, vast industry and application experience, and our team of dedicated engineering and manufacturing specialists ensure that each product we produce is built precisely as your application requires. To learn more about us, including compliance and quality information, click learn more.

Industries

Our engineering team is well-versed in custom manufacturing for products for multiple industries, including those listed here.

Questions? Get in Touch.

We have an expert team of engineers and manufacturing professionals on staff. Email us at sales@heli-cal.com or call us at 805.928.3851 if you have questions about our services, need design support, or simply want to get in touch with an expert. Or click the link to contact us.